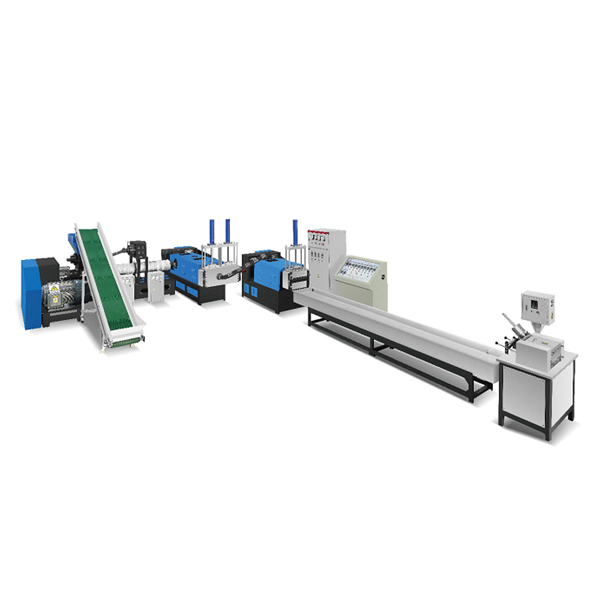

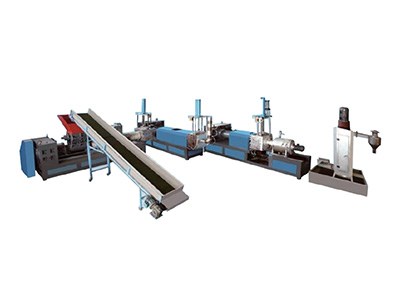

Three Stage Water Cooling PP PE Plastic Granulator

More videos check here!

Sample Pictures:

Details: customized service is available

Main Features:

Recycled plastic granulator, suitable for high and low pressure, polypropylene and other plastic regeneration granulation, the machine is equipped with automatic constant temperature control, electric or manual filter screen device, if the use of grinding granulation.

The granulating machine adopts sliding motor speed control, which can be synchronously cut according to the discharge speed of the host machine. This machine has the characteristics of high output, low noise, stable performance, easy operation, etc. It is a kind of ideal waste plastic film regeneration granulation model.

Main Technical Parameters:

| Model | 200 |

| Screw diameter | 1 st: Φ200

2 nd: Φ200 3 rd: Φ200 |

| Screw L/D ratio | 1 st 14:1

2 nd 13:1 3 rd 8:1 |

| Screw rotation | 10-100 rpm |

| Max. Extrusion output | 600 kg/h |

| Main motor power | 110+55+37kw |

| Machine weight | 10 t |

| Machine Size | 12000*8000*2000mm |

Please note: suntone company is continuously seeking for development of products. For this reason, suntone reserves the right to supply the improved product without advance notice.

plastic granulator, granulator, granulating equipment, pellet machine, pelletizing machine, pelletizer, recycling machine,

Optional (additional fee required):

Please consult us for this information

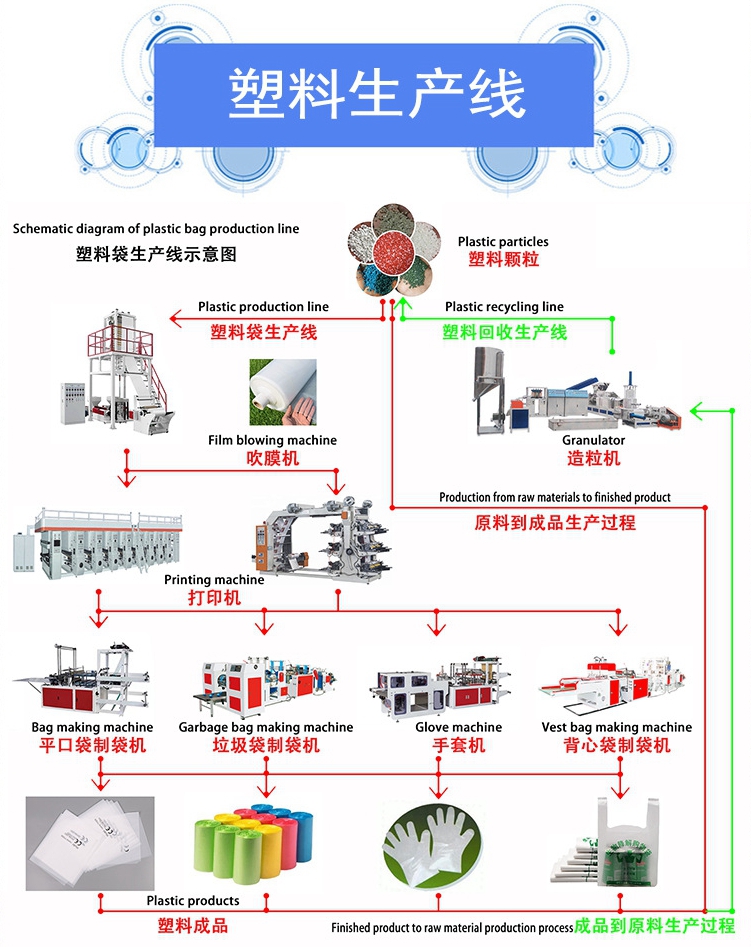

Product Production Process:

What Sets Us Apart:

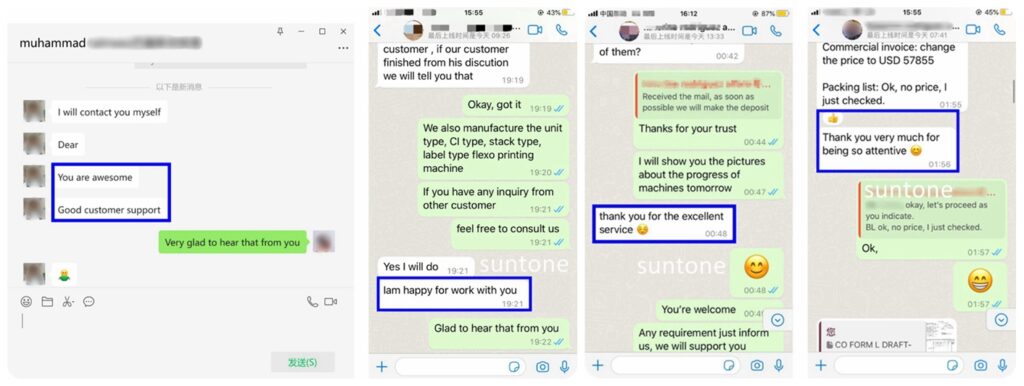

What Does The Clients Say:

Packaging & Delivery:

FAQ:

Q: What’s the price of machines?

A: Pls provide following information:

1) What’s your waste material? HDPE, LDPE,PP or ABS?

2) Is it hard or soft material?

3) Is it dirty or clean material?

4) What’s your capacity?