Plastic HDPE LDPE Blown Film Extruder Machine

More videos check here!

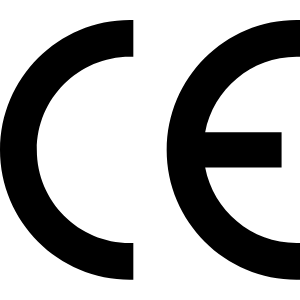

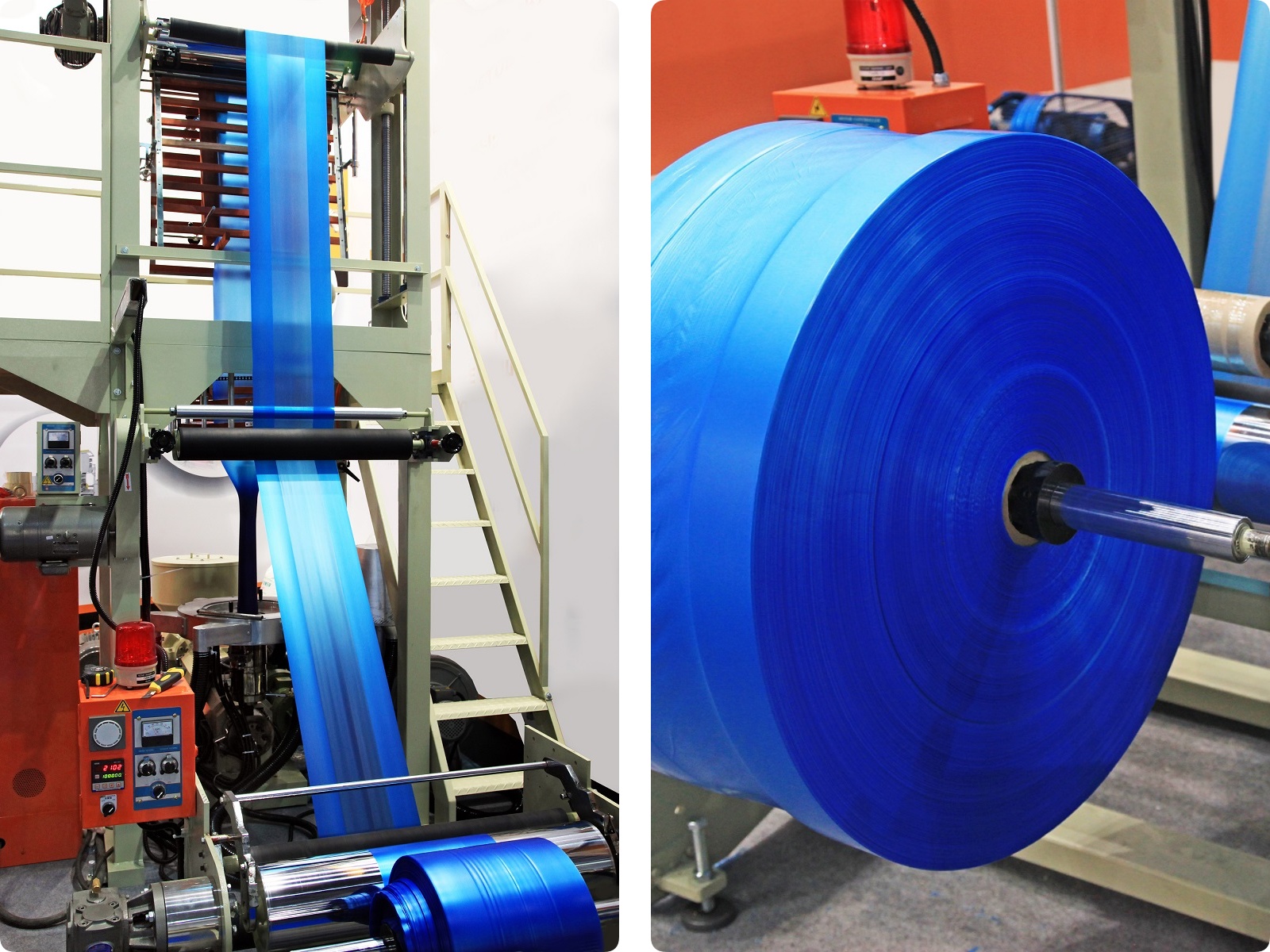

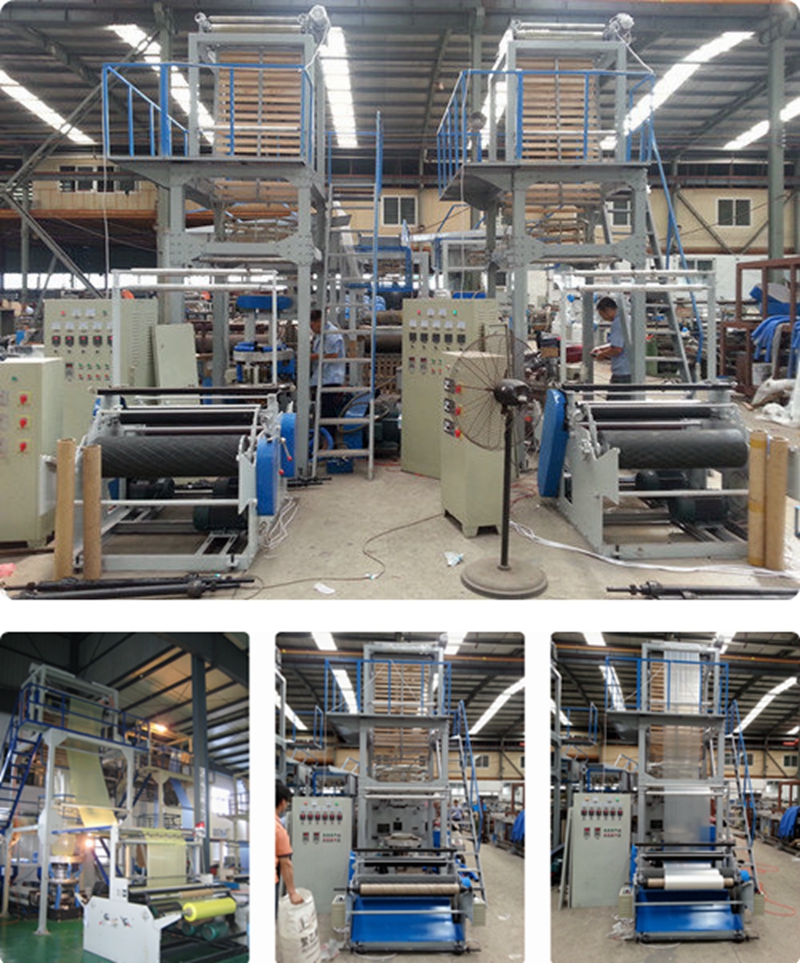

Sample Pictures:

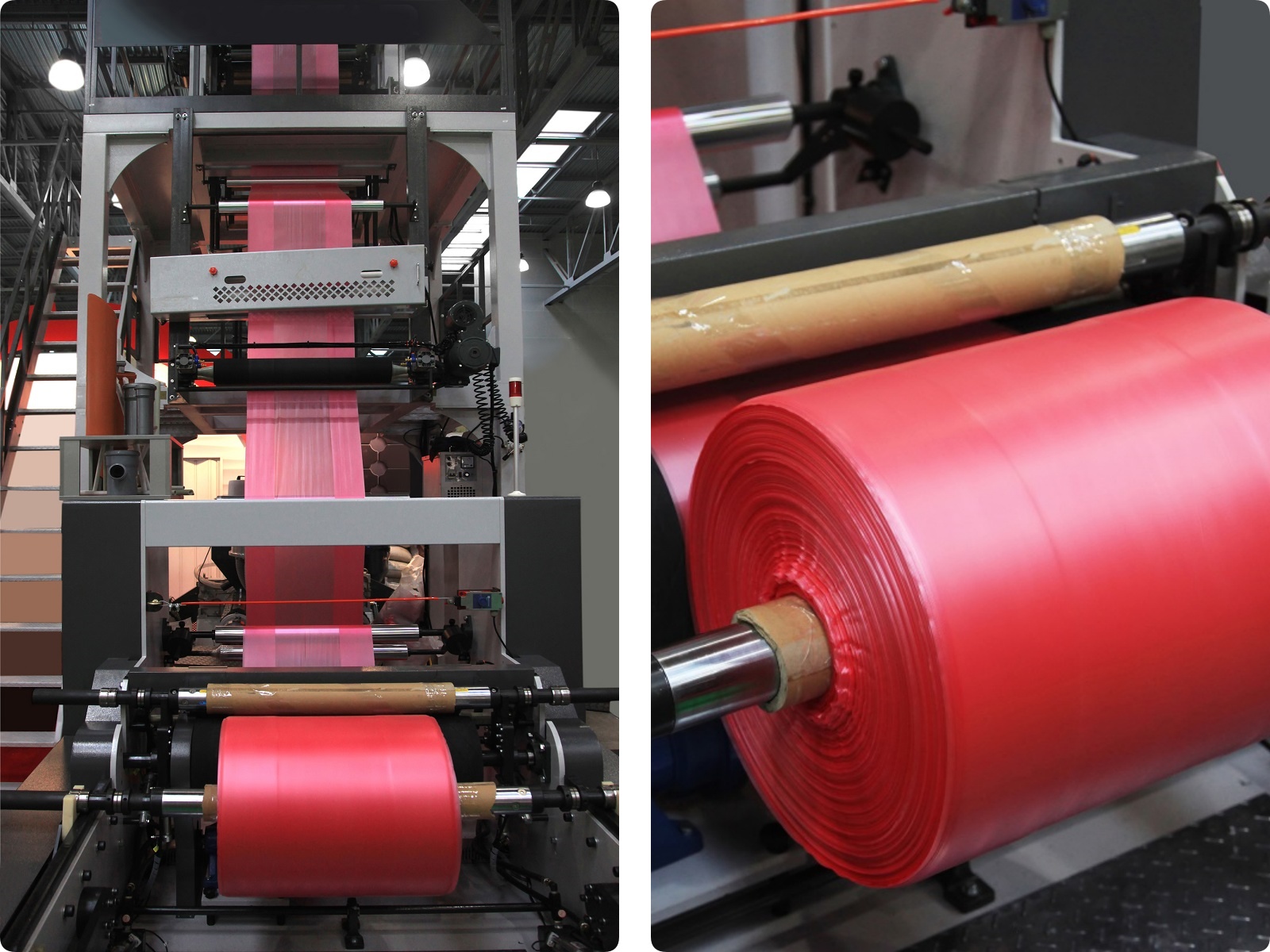

Details: customized service is available

Main Performance:

It is applied to blowing the plastic films like LDPE, HDPE and LLDPE, widely applied to producing the packing bags for foodstuff, clothing, rubbish bag and vest bags. Packaging film has good insulation, for instance holding temperature, anti-humid, anti-freeze, anti-rain, anti-rost, insulation oxygen, oil resistive, and so used for light and heavy-duty packaging, for example fresh fruits, meats, salt vegetables, fresh milk, drink and so on.

Main Features:

Its extruder, cylinder and screw are made of quality alloy steel which have been nitrized and processed in a precision way. Hence it is sound in hardness, durable in corrosion resistance. The specially-designed screw is of sound quality in plasticizing, which helps increase the production capacity.

Main Technical Parameters:

| Model | H45/50 | H55 | H60 | H65 |

| Suitable Material |

HDPE/LDPE/LLDPE | HDPE/LDPE/LLDPE | HDPE/LDPE/LLDPE | HDPE/LDPE/LLDPE |

| Max Film Width(mm) | 600 | 800 | 1000 | 1200 |

| Film Thickness(mm) | HD:0.008-0.08 | HD:0.008-0.08 | HD:0.008-0.08 | HD:0.008-0.08 |

| Max Extrusion Output HD | 30/40kg/hr | 50kg/hr | 60kg/hr | 80kg/hr |

| Extrusion Unit | ||||

| Gear Box | 133/146 | 173 | 173 | 200 |

| Screw Diameter(mm) | φ45/50 | φ55 | φ60 | φ65 |

| Screw’s Material | 38 CRMOALA | 38 CRMOALA | 38 CRMOALA | 38 CRMOALA |

| Barrel’s Material | 38 CRMOALA | 38 CRMOALA | 38 CRMOALA | 38 CRMOALA |

| Barrel’s Cooling Fan | 200W*2 | 200W*2 | 200W*2 | 200W*2 |

| Thermo Control (zone) | 3 | 3 | 3 | 4 |

| Driving Motor (kw) | 7.5/11 | 18.5 | 22 | 30 |

| Extrusion Die | ||||

| Die Size (mm) | HD:φ60/80 | HD:φ80/100 | HD:φ100/120 | HD:φ120/150 |

| Screen changer | Standard manual | Standard manual | Standard manual | Standard manual |

| Thermo Control(zone) | 2 | 2 | 2 | 2 |

| Air Ring | φ620 | φ620 | φ620 | φ760 |

| Cooling Blower(kw) | 1.5 | 2.2 | 2.2 | 3 |

| Take-up Unit | ||||

| Roller Width(mm) | φ138*650 | φ138*850 | φ138*1100 | φ138*1300 |

| Embossing roller width | 550mm | 750mm | 1100mm | 1200mm |

| Take-UP Motor (kw) | 0.75 | 1.1 | 1.1 | 1.5 |

| Take-UP Speed(M/min) | 10-60 | 10-60 | 10-60 | 10-60 |

| Height adjustable type | 700mm | 700mm | 700mm | 700mm |

| Winding Unit | ||||

| Type of Winder | Surface friction winder | Surface friction winder | Surface friction winder | Surface friction winder |

| Roller Width (mm) | 700 | 900 | 1100 | 1300 |

| Winding Motor(KW) | 6 | 10 | 10 | 16 |

| Winding Speed(M/min) | 10-60 | 10-60 | 10-60 | 10-60 |

| Voltage | 380V/50HZ/3PHASE | 380V/50HZ/3PHASE | 380V/50HZ/3PHASE | 380V/50HZ/3PHASE |

| Cover Dimension(m) | 4.5*2*4.3 | 4.5*2.2*4.5 | 5*2.5*4.8 | 5.5*2.8*5.2 |

Please note: suntone company is continuously seeking for development of products. For this reason, suntone reserves the right to supply the improved product without advance notice.

blown film extruder machine, extrusion blow molding machine, plastic film blowing machine, film blowing machine,

Optional (additional fee required):

Please consult us for this information

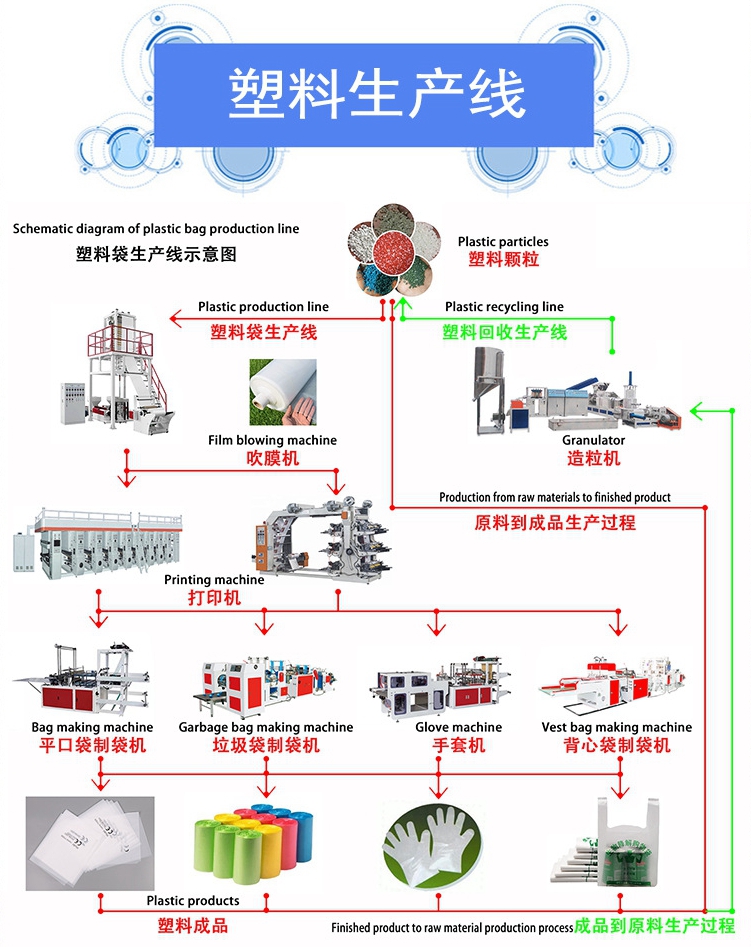

Product Production Process:

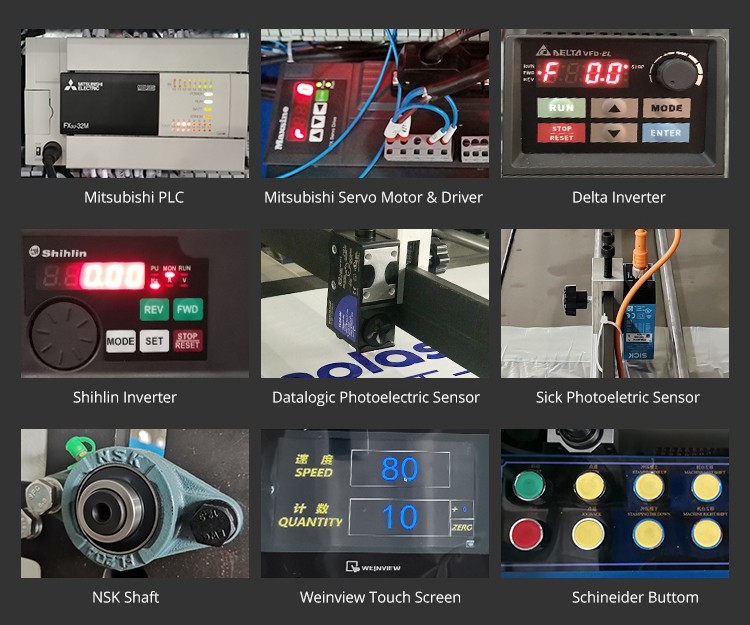

What Sets Us Apart:

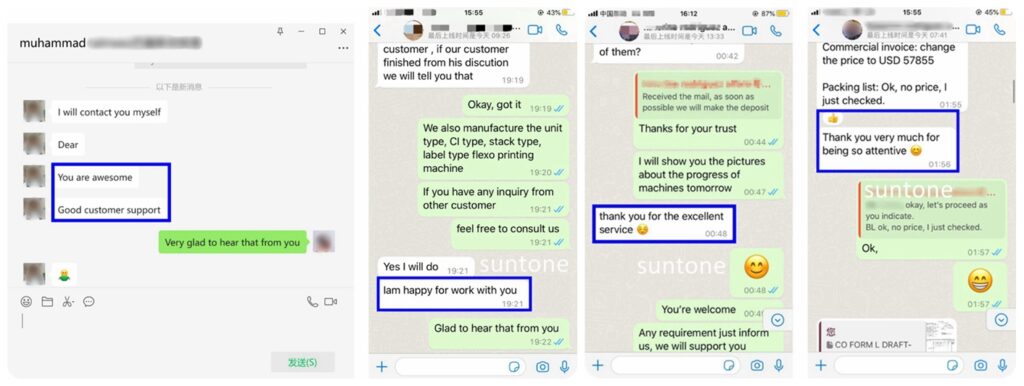

What Does The Clients Say:

Packaging & Delivery:

FAQ:

Q: What’s the price of machines?

A: Pls provide following information:

1) What is your material? Hdpe ldpe or PP?

2) What’s the maximum and minimum width of film?

3) What’s the thickness?

4) You also can let us know the screw dia. As like 45 50 55 60 65 etc.