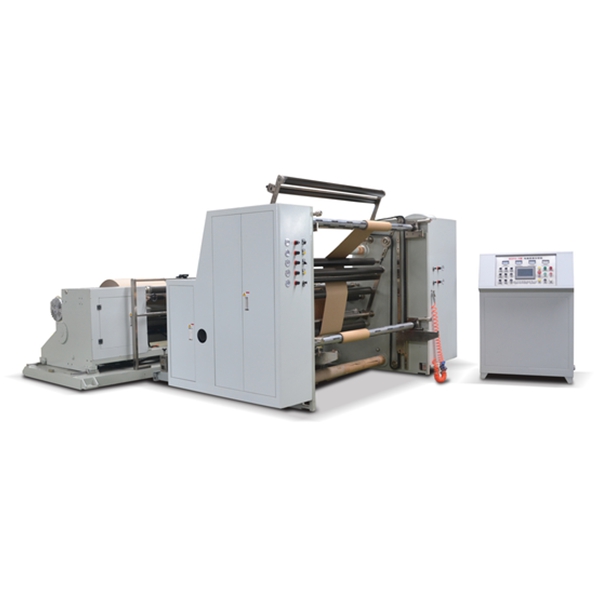

Paper Slitting Machine

More videos check here!

Sample Pictures:

Details: customized service is available

Main Features:

The machine adopts the central rewinding method, which is suitable for all kinds of large coiled materials. In particular, paper handle patch and paper twisted rope etc. raw paper rolls’ slitting and rewinding for paper bag making industry.

It can work with kraft paper, copperplate paper, coated paper and other base paper. Paper thickness range is 50-300gsm.

Three-servo-motor control, automatic taper tension control, automatic meter counting, alarm function, etc. Adopt round knife slitting device, leaf type inflatable shaft A, B structure, and equipped with automatic unloading device, greatly saving manpower. Most operation steps could be done via touch screen, easy to operate.

Main Technical Parameters:

| Model | A1100 | A1300 | A1600 |

| Max. material width | 1100mm | 1300mm | 1600mm |

| Min. slitting width | 30mm | 30mm | 30mm |

| Paper thickness | 50-600gsm | 50-600gsm | 50-600gsm |

| Max. unwind diameter | φ1500mm | φ1500mm / φ1600mm | φ1500mm / φ1600mm |

| Max. rewind diameter | Φ1000mm | φ1000mm | φ1000mm |

| Max. speed | 360m/min | 360m/min | 360m/min |

| Slitting precision | ≤±0.15mm | ≤±0.15mm | ≤±0.15mm |

| Total power | 19kw | 21.5kw | 23.5kw |

| Voltage request | 380V/50Hz | 380V/50Hz | 380V/50Hz |

| Weight | ≈3000kgs | ≈4000kgs | ≈5500kgs |

| Overall dimension (LxWxH) | 3300x3200x1930mm | 3300x3400x1930mm | 3300x3700x1930mm |

Please note: suntone company is continuously seeking for development of products. For this reason, suntone reserves the right to supply the improved product without advance notice.

paper slitter machine, slitting machine, slitter machine, slitter rewinder machine for sale, slitter rewinder machine, slitting rewinding machine, slitting and rewinding machine,

Optional (additional fee required):

Please consult us for this information

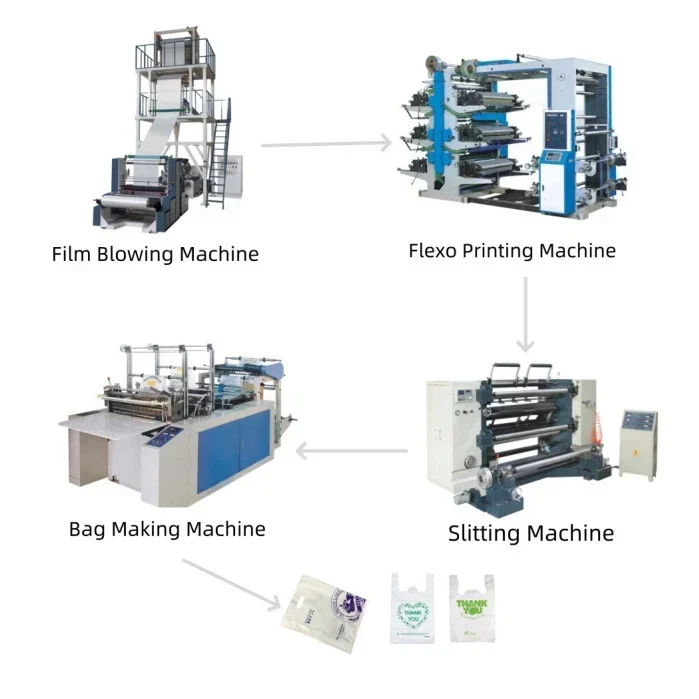

Product Production Process

What Sets Us Apart:

What Does The Clients Say:

Packaging & Delivery:

FAQ:

Q: What’s the price of machines?

A: Pls provide following information:

1) What’s the product that needs to be cut (film, paper, non-woven, etc.)

2) What’s the diameter of the rolling material?

3) What’s the diameter of the finish material?

4) What’s the slitting width?

5) What’s the maximum and minimum dimensions including the thickness?