Automatic Carry Bag Making Machine Bottom Sealing

More videos check here!

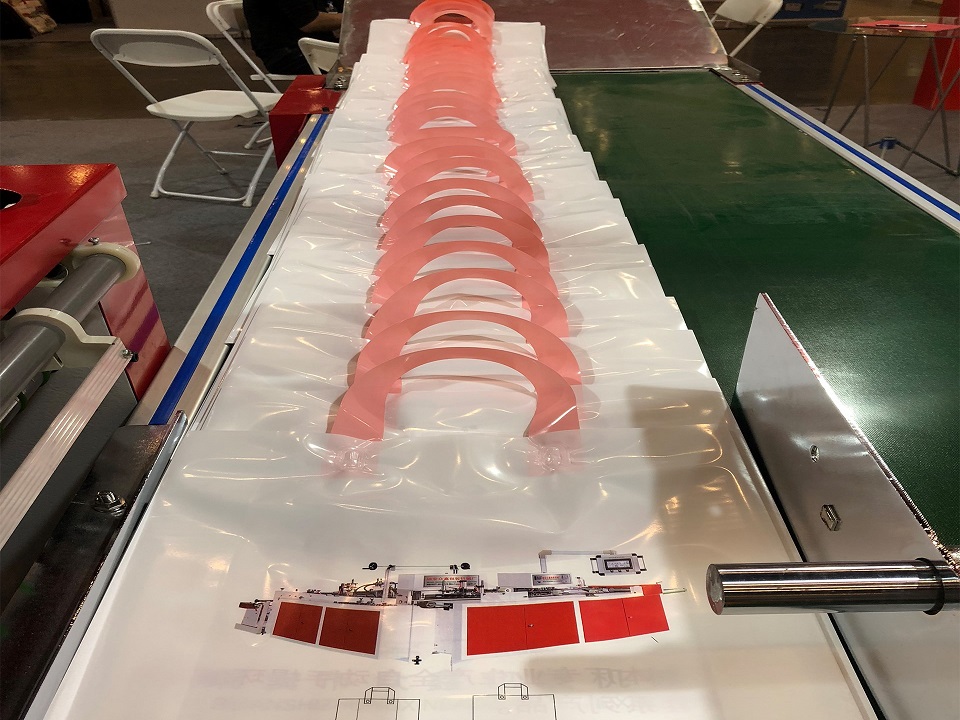

Sample Pictures:

Details: customized service is available

Machine Introduction:

The machine plugs the suitable raw material for the plastic edge material, equipment production, bags hot position strong, beautiful, upscale, generous, can be repeatedly used, mainly for the production of plastic bags, plastic packaging bags, shoe boxes, garment bags and other low-grade plastic bags.

The mechanical and electrical-body cylinders. Together with the optical length, photoelectric tracking, automatic orientation, deviation, accurate, smooth, automatic counting, you can set count alarm, automatic heat knob, automatic pile of bags and other industrial devices. It is the best advanced plastic bag making equipment on the market.

Main Features:

1、The Operating control switch in front and back of the machine, It’s easy to operating.

2、Raw material tension can be automatically adjusted if the machine running (Automatic tension control system is adopted for feeding).

3、The machine adopts pneumatic loading, Air pressure can controllable.

4、The speed of feeding is controlled by Proximity switch.

5、The sealing cut of bag making machine use three – phase asynchronous motor, frequency conversion speed regulation.

6、No Stretch by servo, Hot sealing smooth and beautiful.

7、spring cutting, Long service life.

8、Automatic tally, (bag making counting or loop handle counting).

9、The speed of Transfer Belts adopt frequency conversion speed regulation, the discharging is more orderly and smooth.

Main Technical Parameters:

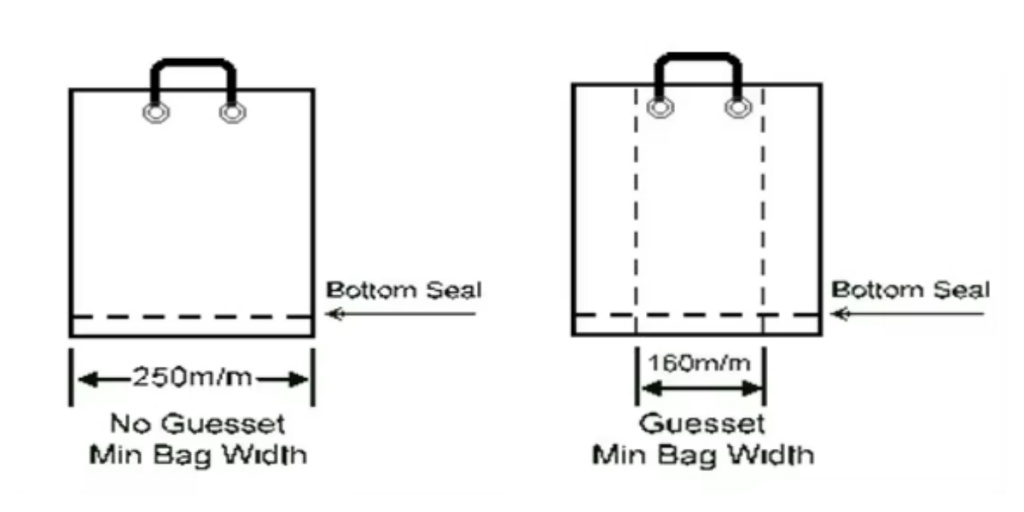

| Model | ASL-600 | ASL -800 | ASL -1000 |

| Max. Bag width | 250mm-550mm | 250mm-750mm | 250mm-950mm |

| Max. Bag length | 350mm-580mm | 350mm-780mm | 350mm-980mm |

| Max. Bag sealing width | 600mm | 800mm | 1000mm |

| Max. Bag cutting length | 600mm | 800mm | 1000mm |

| Max. core diameter | 800mm | 800mm | 800mm |

| Bag thickness | 0.05-0.2mm | 0.05-0.2mm | 0.05-0.2mm |

| Bag making speed | 45-60pcs/min | 45-60pcs/min | 45-60pcs/min |

| Handle length | 330-370mm

usually is 350mm |

330-370mm

usually is 350mm |

330-370mm

usually is 350mm |

| Handle width | 25-50mm

usually is 30mm |

25-50mm

usually is 30mm |

25-50mm

usually is 30mm |

| Power supply | AC 380V,50Hz | AC 380V,50Hz | AC 380V,50Hz |

| Machine weight | 2600kg | 2700kg | 2800kg |

| Machine size (LxWxH) | 4500 x 3600 x 1700mm | 4500 x 3800 x 1700mm | 4500 x 4000 x 1700mm |

Please note: suntone company is continuously seeking for development of products. For this reason, suntone reserves the right to supply the improved product without advance notice.

carry bag making machine, shopping bag making machine, biodegradable bag making machine, d-cut bag making machine, soft loop handle bag making machine, plastic bag making machine, plastic bag maker,

Optional (additional fee required):

Please consult us for this information

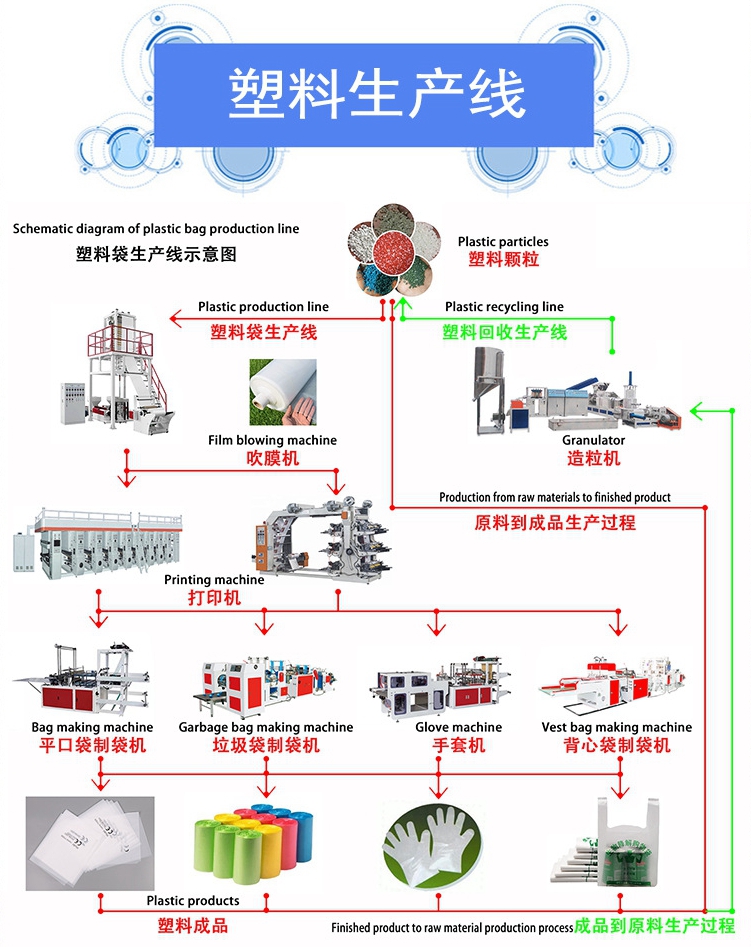

Product Production Process:

What Sets Us Apart:

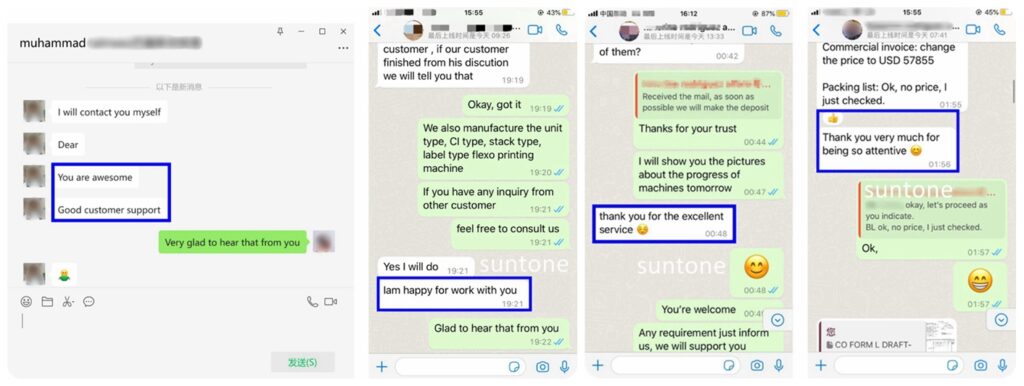

What Does The Clients Say:

Packaging & Delivery:

FAQ:

Q: What’s the price of machines?

A: Pls provide following information:

1) What’s the size of the bag?

2) What’s the thickness of the bag?

3) For which kind bags? If possible, please send us the pictures of bags.